Pioneers In Creating Opportunities

Expertise in Oilfield Technology & Service

Technology

Other Projects & Products

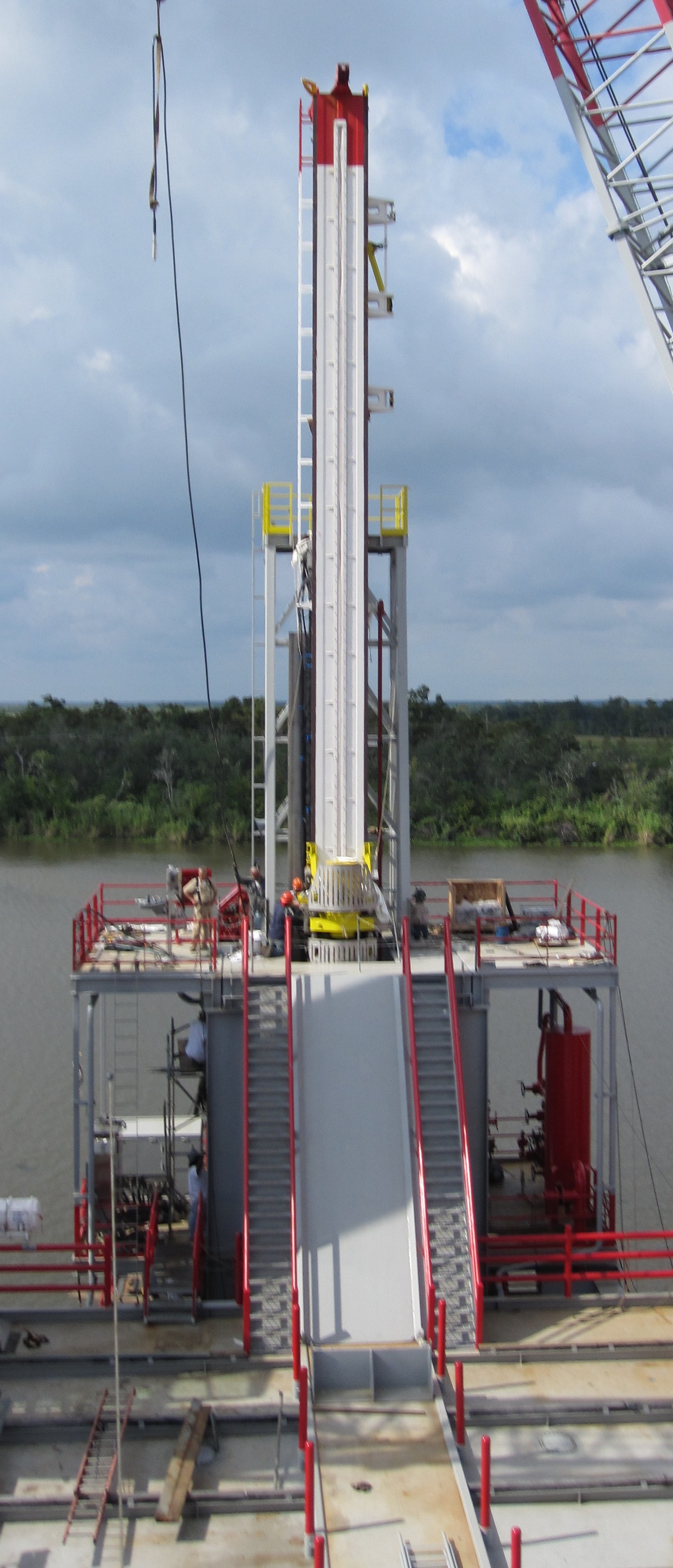

PICO IV Lift Boat

PICO Technologies's Team Coordinated buidling PICO IV Lift Boat with Other subsidaries of PICO Energy Group and other Major manufacturers, Ship yards and suppliers in USA.

Thus Opened opportunitie for PICO Mexico and PICO Marine; the first subsidiary of an Egyptian company PICO Energy to perform services for Pemex in the Gulf of Mexico using PICO IV.

- Class: American Bureau of Shipping Certified for being inspected and overviewed during manufacturing and commissioning

- Leg length: 280 ft (highest class in the world)

- Cranes capacity: 400 MTons (capable of lifting complete platforms)

- Free deck space: 11,000 sqft

- Jacking up/down total time: 45 mins (4-6 hours for Jack up rigs)

- Elevated-conditions wind speed: 100 knots

- Operational wind speed: 70 knots

- Operational swell: 15 ft

- Accommodation: 50 men on board

- The only DP (Dynamically Positioned) Lift Boat in the world enabling the lift boat to approach platforms without interrupting operations

- The only SNAME (Weather resistant) compliant

- The only Sonar equipped for sea bed imaging during legs jacking up

- Unmanned work over rig which elevates the safe working conditions to more than 35 knots

- Eliminates the need for tug boats for travel/positioning

- The 45 min jacking speed eliminates the need for a long suitable weather window for jacking up which reduces the waiting on weather total time by more than 50%

- Fully equipped with cranes, pumps, tanks, logging unit, slick line, testing, snubbing unit/work over rig, coil tubing & stimulation equipment which eliminates the waiting on supply/contractors

- In addition to being suitable for large platforms, it is also equipped with an additional cantilever skid out deck which eliminates any weight loading on monopod/aging platforms

Rig for Sale

-

- Surplus Finder UltraSingle 125T Rack & Pinion Rig. Skid mounted.

- Owner: PICO Energy Integrated Services

- Builder: TTS Sense Canada LTD.

- Date of Manufacture DOM: 2009

- Base Rig Package:

- 125T Mast Skid Base c/w Mast Tower Support System;

- 125T Mast, Mast: 25 m;

- Hydraulic Rack and Pinion Hoisting System;

- Sense EDM Work Over Rig Control System complete with (1) Operators Console;

- Hydraulic Traveling Rotary Table complete with (2) 11" Hydraulic Power Slips;

- (2) Utility Winches;

- (1) Boom Line Winch;

- (1) 3" 5000psi Stand Pipe;

- (1) Diesel Driven HPU to supply the rig, and the client supplied coiled tubing system;

- (1) 11" Hydraulic Power Slip to be mounted to client supplied Drill Floor;

- 120 Gallon Accumulator System complete with drillers panel to be mounted in vilest supplied driller control room

Production Optimization

Artificial Lift

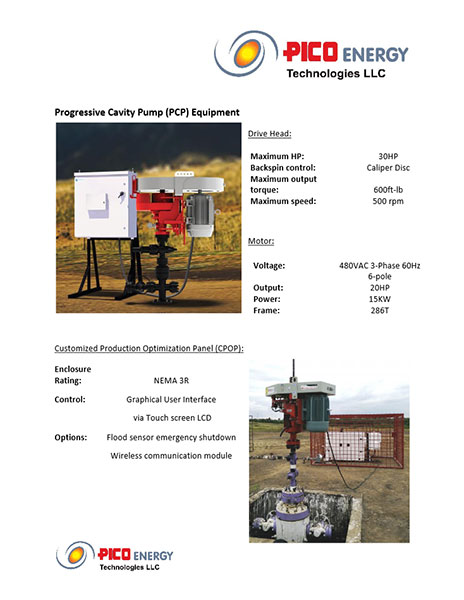

Production optimization control systems for Progressive Cavity Pump systems: (CPOS)

PICO Technologies Customized Production Optimization Panel (CPOP) control system is designed primarily for heavy oil applications with the goal of optimizing production, improving efficiency and extending run life of the pump. The system collects data from artificial lift operations and provides the critical information required to increase production and minimize down time. CPOP provides data gathering on everything from power quality to well performance degradation so that manpower can be spent managing problems rather than identifying them. The system’s flexibility allows the scalable control of driveheads of power ratings from 0.5– 30 (from ABB manual) horsepower from major manufacturers such as KUDU, NOV, and others.

PICO Technologies Customized Production Optimization Panel (CPOP) control system is designed primarily for heavy oil applications with the goal of optimizing production, improving efficiency and extending run life of the pump. The system collects data from artificial lift operations and provides the critical information required to increase production and minimize down time. CPOP provides data gathering on everything from power quality to well performance degradation so that manpower can be spent managing problems rather than identifying them. The system’s flexibility allows the scalable control of driveheads of power ratings from 0.5– 30 (from ABB manual) horsepower from major manufacturers such as KUDU, NOV, and others.

Overview of Wireline Open Hole Logging

Overview of Wire line Logging

What is meant by the terms Wire line logging? Logging can be defined as the systematic recording of data in wells being drilled or produced to obtain various characteristics of down hole formations. In other words, logging furnishes quantitative evaluation of hydrocarbons in place in formation. There are many different types of logs that can be run depending on the information desired. The different types of logs and the tools that are used to run them are covered later in the document.

Solutions Logging Provide

Formation evaluation is critical when making decisions about a well. Customers want to know accurate information regarding the formations they are drilling or completing.

Question customers ask include:

- What types of fluids are there?

- Where are these fluids?

- Are the zones porous?

- How thick are the zones?

- Are the zones permeable?

- What type of rock?

Logging answers these questions by providing a wealth of information on the rock and fluid properties of the formations penetrated including:

- Water saturation

- Types of hydrocarbons present and their mobility

- Permeability

- Lithology

- Structure

- Images

- Rock and fluid samples

Accurately predicting the producibility of hydrocarbons found in place is achieved by analyzing the large amount of data sent uphole by logging tools. Research and development continues to improve the accuracy and reliability of logging tools available.

Basic Measurements and the Archie Equation

The basic measurements taken by logging tools in a wellbore are porosity and resistivity. Porosity is a measure of the total volume between the rock grains. Resistivity is the ability of a material to pass an electric current. The basic results gained by these measurements gives the fraction or percentage of the formation pore space that is occupied by water. This is known as water saturation. If the water saturation of a formation is known this tells us the amount of hydrocarbons because what is not water must be hydrocarbons. The basic measurements and result make up the Archie equation shown below.

The Archie Equation

The Archie equation is a convenient method of identifying fluid type in a clean formation. It requires the inputs of resistivity and porosity as well as other variables and exponents determined from core data or, where core data is lacking, by assumption. The resulting value of water saturation refers to the percentage of pore space that is occupied by water. Any remaining fraction of pore space not occupied by water will therefore be occupied by hydrocarbons. It is important to realize that while water saturation represents the percentage of water present in the pores of a formation, it does not imply a ratio of water to hydrocarbons that will be produced from a reservoir. The Archie equation simply provides us with the relative proportions of water and hydrocarbons contained within a reservoir. This equation was introduced by Gus Archie as a footnote in a 1942 publication, and has since become the foundation on which all logging technological and analytical innovations are built.

Open Hole Services

Openhole logging provides a continuous record vs. depth of many formation properties. Wireline logs record formation electrical resistivity, bulk density, natural and induced radioactivity, and hydrogen content. Measurements obtained are interpreted to give a continuous record versus depth for formation properties such as porosity, water saturation, and rock type.

PICO Technologies tools can be categorized into Induction Resistivity tools, Porosity/Lithology tools, Imaging tools, and specialty tools.

Induction Resistivity Tools

Induction Resistivity tools use electromagnetic signals to determine formation properties. This tool:

Porosity and lithology tools use properties of radiation and sonic signals to provide formation data. These tools include:

- PICO Telemetry Natural Gamma (PTNG)

- PICO Telemetry Spectral Gamma (PTSG)

- PICO Compensated Neutron Tool (PCNT)

- PICO Compensated Spectral Density Logging Tool (CSDL)

Future Projects and tools: “Link”

- Imagining tool

- Sonic Tool

- Dual Laterlog

- Formation Tester

2 1/4” Slim Triple Combo Tools

- Telemetry

- Natural Gamma

- Spectral Gamma

- Neutron

- Density

- Thin Bed Array Induction